Optimising Pre-Manufacturing Processes including planning and scheduling for a Global Pharmaceutical Leader.

Challenges

About the Client:

A leading global provider of pharmaceutical technologies and specialty chemicals, known for its expertise in specialty excipients and film coating systems. The company operates a complex ‘Make to Order’ model, managing thousands of formulations and finished goods across a global network of plants.

The organisation wanted to automate the pre-manufacturing steps of 100% of batches scheduled into the system thereby reducing many of its repetitive manual tasks and increasing manufacturing capacity with optimisation of equipment maintenance and downtimes.

- Inefficient pre-manufacturing processes resulting in excessive manual tasks and workflows.

- High staff time and operational waste, limiting growth capacity.

- Requirement to maximise utilisation of processes and assets while preparing for eventual ERP modernisation and Cloud transformation.

- Need to automate pre-manufacturing steps for all batches to improve manufacturing capacity and optimise equipment maintenance.

Solution

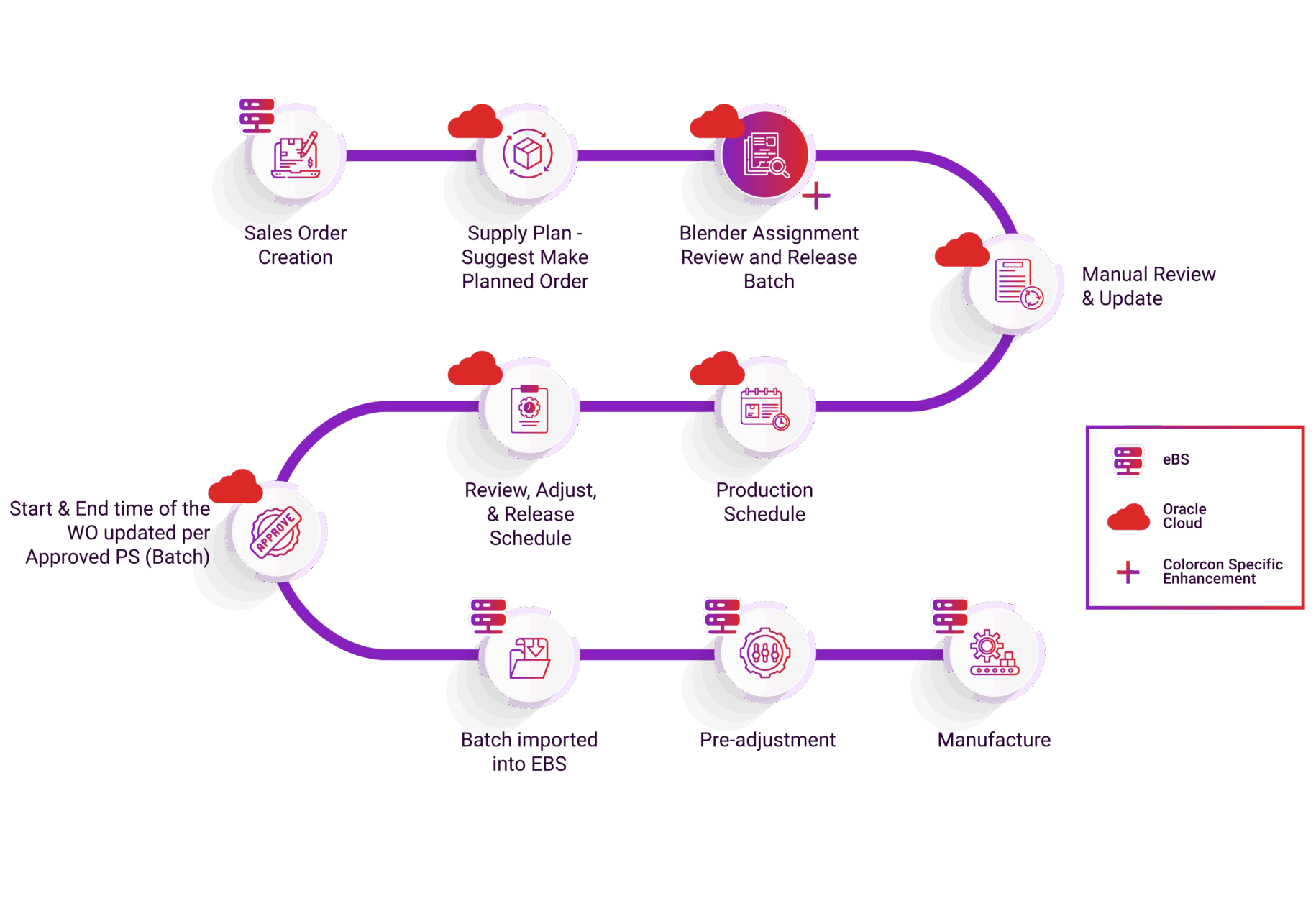

InspireXT led a discovery exercise leveraging Oracle Fusion Cloud Planning and associated SaaS platforms components and proposed the following solution components:

- Supply Planning: Consolidation of booked sales orders and optimised resource allocation (blenders, operators) using Oracle Fusion Cloud.

- Production Scheduling: Creation of detailed schedules considering shift timings, resource capacity, planned downtime, and batch sequencing.

- Custom Extensions: Assigning the most suitable equipment based on capacity constraints to reduce manual intervention.

- Integration: Seamless integration using Oracle Integration Cloud Infrastructure.

Results

- Reduced manual tasks and inefficiencies, lowering labor costs and operational expenses.

- Increased capacity and optimised utilisation of pre-manufacturing processes and

assets. - Established a scalable foundation for future cloud transformation and ERP modernisation.

- Advanced corporate objectives of automation, modernisation, and securing long-

term operational efficiency.

The Opportunity

About the Client:

A leading global provider of pharmaceutical technologies and specialty chemicals, known for its expertise in specialty excipients and film coating systems. The company operates a complex ‘Make to Order’ model, managing thousands of formulations and finished goods across a global network of plants.

The organisation wanted to automate the pre-manufacturing steps of 100% of batches scheduled into the system thereby reducing many of its repetitive manual tasks and increasing manufacturing capacity with optimisation of equipment maintenance and downtimes.

- Inefficient pre-manufacturing processes resulting in excessive manual tasks and workflows.

- High staff time and operational waste, limiting growth capacity.

- Requirement to maximise utilisation of processes and assets while preparing for eventual ERP modernisation and Cloud transformation.

- Need to automate pre-manufacturing steps for all batches to improve manufacturing capacity and optimise equipment maintenance.

The Solution

InspireXT led a discovery exercise leveraging Oracle Fusion Cloud Planning and associated SaaS platforms components and proposed the following solution components:

- Supply Planning: Consolidation of booked sales orders and optimised resource allocation (blenders, operators) using Oracle Fusion Cloud.

- Production Scheduling: Creation of detailed schedules considering shift timings, resource capacity, planned downtime, and batch sequencing.

- Custom Extensions: Assigning the most suitable equipment based on capacity constraints to reduce manual intervention.

- Integration: Seamless integration using Oracle Integration Cloud Infrastructure.

The Outcome

- Reduced manual tasks and inefficiencies, lowering labor costs and operational expenses.

- Increased capacity and optimised utilisation of pre-manufacturing processes and

assets. - Established a scalable foundation for future cloud transformation and ERP modernisation.

- Advanced corporate objectives of automation, modernisation, and securing long-

term operational efficiency.

Request for services

Find out more about how we can help your organisation navigate its next. Let us know your areas of interest so that we can serve you better.