InspireXT Leverages Oracle Fusion ERP’s Product Recall Management to Empower Global Brands with Faster, Smarter Recalls

- Santosh Kore

The Pressure Today

When a supplier reports a defective batch or a quality issue, every minute counts.

For many organizations, handling recalls is still a slow and manual process teams scramble through spreadsheets, emails, and separate systems just to trace where the affected items went.

This lack of visibility can delay the recall response, increase compliance risk, and even impact customer trust.

Over the past year, supply chain disruptions and stricter safety regulations have made recall management even more urgent. Companies that still depend on manual recall tracking face audit exposure, delayed supplier recoveries, and potential brand damage.

If nothing changes, the gap between detection and action will only widen and so will the risk.

Industry Reality

Across industries from pharmaceuticals to retail, recalls often expose the weakest part of an organization’s supply chain: traceability.

Most companies struggle in three areas:

- Identification: It’s hard to quickly locate the exact batches or lots affected.

- Coordination: Communication between procurement, inventory, and quality teams is disconnected.

- Response: Supplier returns and financial settlements take days to process manually.

The root cause isn’t lack of effort it’s fragmented systems.

Without a connected recall process, even the best teams end up chasing data instead of managing the issue.

The part of the value chain under the most stress today is inbound quality and supplier management. When suppliers flag defects, organizations must trace the issue immediately before those goods reach customers or production lines.

How It Should Work (Our Point of View)

At InspireXT, we believe product recalls should be fast, connected, and fully traceable not a manual firefight.

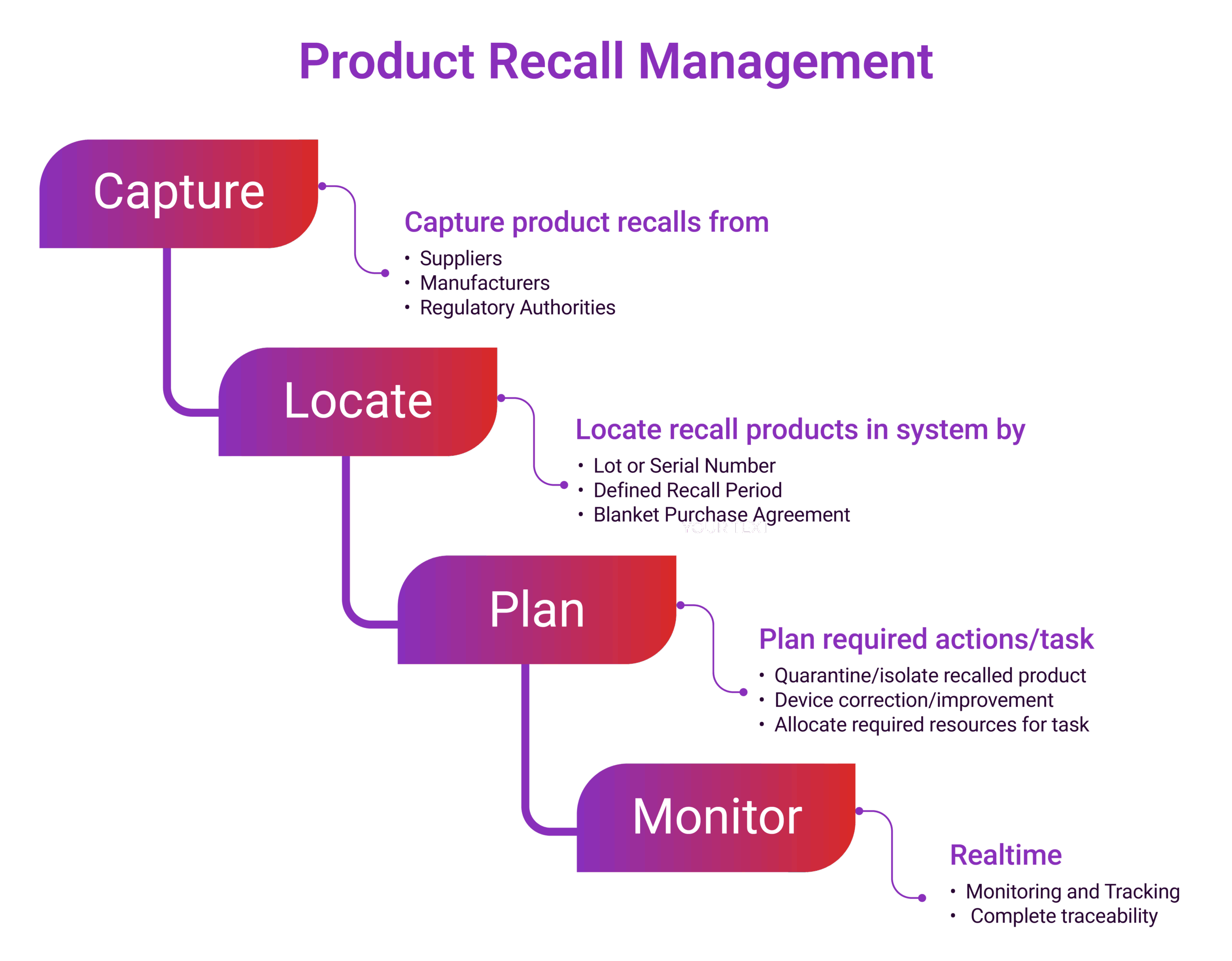

With Oracle Fusion Cloud Product Recall Management, we turn reactive recall handling into a proactive, data-driven process.

The platform connects Procurement, Inventory, Quality, and Payables into one integrated recall ecosystem.

From the moment a supplier flags an issue, the system automatically identifies where the defective products are, triggers tasks for quarantine or return, and initiates financial recovery through debit memos all within Oracle Fusion ERP.

In Short: It’s the process of finding, removing, and replacing those faulty products from the market quickly and safely.

Where many recall processes, fail is in ownership of too many systems, too little accountability. By embedding recall workflows directly inside Oracle Fusion, InspireXT ensures that every action is system-driven, timestamped, and assigned so nothing is missed, and compliance is effortless.

What We Actually Deliver (Leveraging Oracle Fusion ERP for Faster, Smarter Product Recalls)

We focus on configuring and streamlining and leveraging the Product Recall management of Oracle Fusion and make recall process runs smoothly from start to finish right from supplier notification to financial recovery.

Here’s how it works in action:

Let’s take an example,

- A manufacturing company received a shipment of nutritional products from one of its regular suppliers.

The total quantity was received and stored within the organization’s inventory - A few days later, the supplier notified the company that a portion of the shipment was found to be defective and needed to be recalled immediately.

- We start by using Oracle Fusion’s standard workflow to create and publish a recall notice, capturing all the key details like supplier, item, and risk.

- The system then automatically identifies and isolates the affected lots, so teams know exactly where the defective stock is.

- Predefined system tasks guide users to locate, quarantine, and return the recalled stock

- Once the return is completed, a debit memo is automatically generated in Payables, making supplier cost recovery effortless.

- Throughout the process, teams can use built-in dashboards to monitor recall progress and stay audit-ready.

Because Procurement, Inventory, Payables, and Quality modules all connect within Oracle Fusion, everything works together in one seamless flow no extra tools or manual tracking needed.

In the end, InspireXT helping organizations simplify the recall process using what’s already in Oracle Fusion reducing complexity, improving compliance, and acting faster when it matters most.

Proof / Results

What we implemented:

Oracle Fusion Product Recall Management integrated with Inventory and Payables, automating lot identification, quarantine, and supplier returns.

What changed:

The recall process that once took days was reduced to just a few hours. Every affected lot was automatically quarantined, tracked, and returned with complete audit visibility.

What Comes Next

As supply chains grow larger, recalls don’t stop at the supplier stage, they can also reach customers and distributors.

With Oracle Fusion Product Recall Management, we can easily find which customers received the affected items, send recall notifications, and manage returns or replacements all from the same system. This helps close the loop between supplier and customer, ensuring every recall is faster, traceable, and compliant.

Ready to take the next step? Let’s turn these ideas into reality. Reach out today to explore how we can help you implement this feature or tailor it to your needs.

Request for

services

Find out more about how we can help your organisation navigate its next. Let us know your areas of interest so that we can serve you better.